you could combine the battery per light idea with the thread wire plan and hook a couple of lights up in parallel, giving you short 'runs' of lights where you want them...

Batteries for each run can be hidden in small folds of black fabric etc. and single CR2032s (button batteries available on ebay or the $ store near you) are light enough they shouldn't change the flow of the garment much...

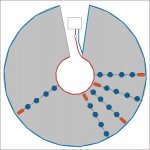

(parallel means all the + sides of the lights (the longer leg) connect to the + side of the battery, all the - to the -, I can draw this if it's unclear)

see how many lights you can light up bright enough per battery (don't forget they'll get a bit dimmer as the batteries drain) and make your runs this many lights long.

Maybe?

Batteries for each run can be hidden in small folds of black fabric etc. and single CR2032s (button batteries available on ebay or the $ store near you) are light enough they shouldn't change the flow of the garment much...

(parallel means all the + sides of the lights (the longer leg) connect to the + side of the battery, all the - to the -, I can draw this if it's unclear)

see how many lights you can light up bright enough per battery (don't forget they'll get a bit dimmer as the batteries drain) and make your runs this many lights long.

Maybe?